Product Description

| 型 號 | 刃數 | 能力 | 外 觀 尺 寸 mm | α | |||||||||||||

| 孔倒角加工 mm | ØD | ØDs | Ødn1 | Ødn2 | Ødi | M | L | ℓn1 | ℓn2 | ℓm | ℓi | S | C | E | |||

| NK1536T-MD | 2 | Ø8~ Ø36 | 37.9 | 8 | 37.8 | 23 | 12.5 | M12 | 63 | 24 | 41 | 22 | 5.5 | 4.0 | 10 | 17 | 15° |

| NK2035T-MD | 2 | Ø8~ Ø36 | 37.1 | 8 | 36.8 | 23 | 12.5 | M12 | 63 | 24 | 41 | 22 | 5.5 | 5.3 | 10 | 17 | 20° |

| NK2535T-MD | 2 | Ø8~ Ø35 | 36.0 | 8 | 35.6 | 23 | 12.5 | M12 | 63 | 24 | 41 | 22 | 5.5 | 6.5 | 10 | 17 | 25° |

| NK3030T-MD | 2 | Ø8~ Ø33 | 34.8 | 8 | 34.1 | 23 | 12.5 | M12 | 63 | 24 | 41 | 22 | 5.5 | 7.7 | 10 | 17 | 30° |

| NK3532T-MD | 2 | Ø8~ Ø32 | 33.3 | 8 | 32.5 | 23 | 12.5 | M12 | 63 | 24 | 41 | 22 | 5.5 | 8.9 | 10 | 17 | 35° |

| NK4031T-MD | 2 | Ø8~ Ø31 | 31.7 | 8 | 30.6 | 23 | 12.5 | M12 | 63 | 24 | 41 | 22 | 5.5 | 9.9 | 10 | 17 | 40° |

| NK4530T-MD | 2 | Ø8~ Ø29 | 29.9 | 8 | 28.5 | 23 | 12.5 | M12 | 63 | 24 | 41 | 22 | 5.5 | 10.9 | 10 | 17 | 45° |

| NK5031T-MD | 2 | Ø12 ~Ø31 | 31.9 | 12 | 30.6 | 23 | 12.5 | M12 | 63 | 24 | 41 | 22 | 5.5 | 11.8 | 10 | 17 | 50° |

| NK5532T-MD | 2 | Ø15 ~ Ø32 | 32.7 | 15 | 31.4 | 23 | 12.5 | M12 | 63 | 24 | 41 | 22 | 5.5 | 12.7 | 10 | 17 | 55° |

| NK6030T-MD | 2 | Ø15 ~ Ø30 | 30.5 | 15 | 28.9 | 23 | 12.5 | M12 | 63 | 24 | 41 | 22 | 5.5 | 13.4 | 10 | 17 | 60° |

| NK6533T-MD | 2 | Ø20 ~ Ø33 | 33.1 | 20 | 31.7 | 23 | 12.5 | M12 | 63 | 24 | 41 | 22 | 5.5 | 14.0 | 10 | 17 | 65° |

| NK7032T-MD | 2 | Ø22 ~ Ø32 | 32.6 | 22 | 31.2 | 23 | 12.5 | M12 | 63 | 24 | 41 | 22 | 5.5 | 14.5 | 10 | 17 | 70° |

| NK7533T-MD | 2 | Ø25 ~ Ø33 | 33.0 | 25 | 31.6 | 23 | 12.5 | M12 | 63 | 24 | 41 | 22 | 5.5 | 15.0 | 10 | 17 | 75° |

●切削條件

| T32MOR | ||||||

| 切削材質 | 材質型號 | NK2001 | NK1010 | NK2020 | NK3030 | AC16N |

| 刀片進給量(mm/刃) | 切 削 速 度 m/分 | |||||

| 普通鋼SS等 | 0.08 ~ 0.2 | 200 ~ 250 | 150 ~ 200 | 150 ~ 200 | 100 ~ 200 | |

| 合金鋼SKD/SCM等 | 0.08 ~ 0.2 | 200 ~ 250 | 150 ~ 200 | 150 ~ 200 | 100 ~ 200 | |

| 不銹鋼SUS等 | 0.08 ~ 0.2 | 100 ~ 150 | 100 ~ 150 | 100 ~ 200 | ||

| 鋁。樹脂。黃銅系列 | ||||||

| 鑄鋼FC/FCD等 | 0.08 ~ 0.2 | 200 ~ 250

※FCD切削時 |

100 ~ 150 | |||

| TT32GURF | ||

| 切削材質 | 材質型號 | TC16N |

| 刀片進給量(mm/刃) | 切削速度m/分 | |

| 耐熱合金

(鉻鎳鐵合金) |

0.02 ~ 0.05 | 150 ~ 200 |

| 鈦合金 | 0.02 ~ 0.05 | 150 ~ 200 |

| TNEA160304 | ||

| 切削材質 | 材質型號 | TC16N |

| 刀片進給量(mm/刃) | 切削速度m/分 | |

| 硬化金合鋼

SKD/HSS等 (HRC50~65) |

0.08 ~ 0.2 | 150 ~ 200 |

| TT32GUR | ||||||||||

| 切削材質 | 材質型號 | NK2001 | NK1010 | NK2020 | NK3030 | NK5050 | NK8080 | AC15N | HSS | HSS TiN |

| 刀片進給量(mm/刃) | 切 削 速 度 m/分 | |||||||||

| 普通鋼SS等 | 0.08 ~ 0.2 | 200 ~ 250 | 150 ~ 200 | 150 ~ 200 | 150 ~ 200 | 13 ~ 23 | 15 ~ 25 | |||

| 合金鋼SKD/SCM等 | 0.08 ~ 0.2 | 200 ~ 250 | 150 ~ 200 | 150 ~ 200 | 150 ~ 200 | 10 ~ 20 | 13 ~ 22 | |||

| 不銹鋼SUS等 | 0.08 ~ 0.2 | 120 ~ 180 | 150 ~ 200 | 120 ~ 180 | 150 ~ 200

※SUS316切削時 |

150 ~ 200 | 10 ~ 15 | 11 ~ 17 | ||

| 鋁。樹脂。黃銅系列 | 0.08 ~ 0.3 | 250 ~ 800 | 250 ~ 800 | 300 ~ 1,000 | 31 ~ 40 | 31 ~ 47 | ||||

| 鑄鋼FC/FCD等 | 0.08 ~ 0.3 | 200 ~ 250

※FCD切削時 |

||||||||

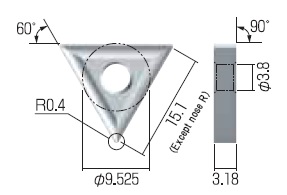

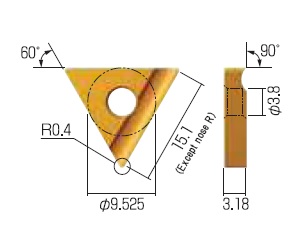

●適用刀片

| 刀片樣式 | 刀片型號 | 材質 | 邊緣形狀 | 塗層 | 使用角數 | 1盒(片) |

|

T32MOR NK2001 | 金屬陶瓷 | 珩磨邊 | 無 | 6 | 12 |

| T32MOR NK1010 | 超硬K10 | 尖銳邊緣 | 無 | 6 | 12 | |

| T32MOR NK2020 | 超硬M20 | 珩磨邊 | 無 | 6 | 12 | |

| T32MOR NK3030 | 超硬M20 | 珩磨邊 | TiN | 6 | 12 | |

| T32MOR AC16N | 超硬M20 | 珩磨邊 | TiAℓN | 6 | 12 | |

|

TT32GUR NK2001 | 金屬陶瓷 | 珩磨邊 | 無 | 2 | 12 |

| TT32GUR NK1010 | 超硬K10 | 尖銳邊緣 | 無 | 2 | 12 | |

| TT32GUR NK2020 | 超硬M20 | 珩磨邊 | 無 | 2 | 12 | |

| TT32GUR NK3030 | 超硬M20 | 珩磨邊 | TiN | 2 | 12 | |

| TT32GUR NK5050 | 超硬K10 | 尖銳邊緣 | TiN | 2 | 12 | |

| TT32GUR NK8080 | 超硬K10 | 尖銳邊緣 | TiAℓN | 2 | 12 | |

| TT32GUR AC15N | 微粒子超硬 | 珩磨邊 | AlCrN | 2 | 12 | |

| TT32GURF TC16N | 微粒子超硬 | 尖銳邊緣 | TiSiN | 2 | 12 | |

| TT32GUR HSS | HSS | 尖銳邊緣 | 無 | 2 | 12 | |

| TT32GUR HSS TiN | HSS | 尖銳邊緣 | TiN | 2 | 12 | |

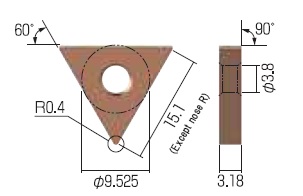

|

TNEA160304 TC16N | 微粒子超硬 | 珩磨邊 | TiSiN | 6 | 12 |